In many industrial or warehouse settings, the default layout is “everything in one big hall.” That may seem simple, but it often causes inefficiency, safety risks, and ambiguity in purpose. That’s where partitioning becomes essential.

The Role of Partitioning

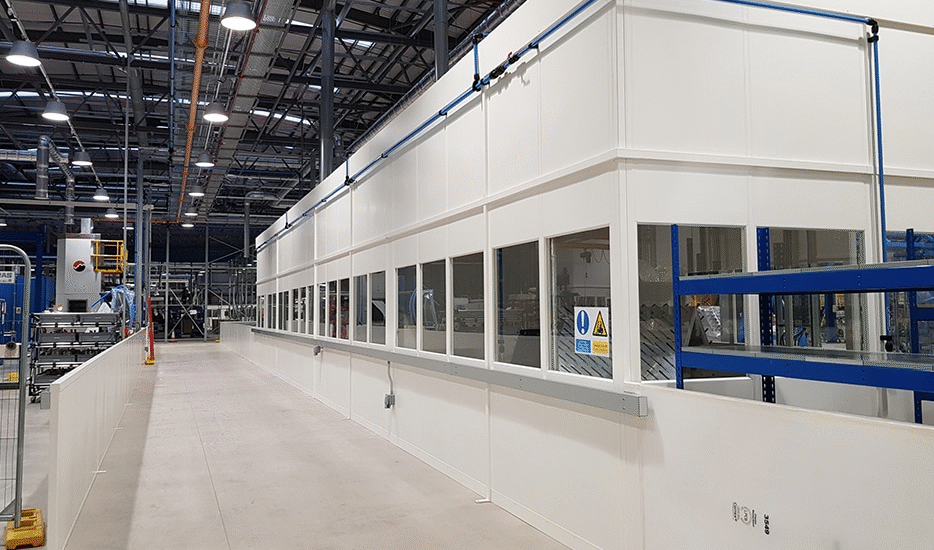

Partitioning means dividing one large space—be it a warehouse, factory, or workshop—into smaller, distinct zones using walls or barrier systems. These aren’t permanent brick walls but modular partitions suited to industrial demands. They can separate manufacturing areas from admin zones, isolate quality control from high-traffic storage, or create secure rooms for sensitive inventory.

Key Benefits

- Safety & Risk Management

By partitioning off hazardous zones—areas with heavy machinery, chemical processing, or high voltage—you keep the rest of the facility safer. You prevent cross-contamination, reduce the risk of accidental entry, and make emergency protocols clearer. - Improved Workflow & Focus

Different functions often need different environments—packing, inspection, offices, storage. Partitioning lets you allocate space accordingly and minimizes interference. Staff in a quiet inspection room can focus without forklift noise or dust from the warehouse floor. - Climate & Environmental Control

Sometimes you need controlled temperature, humidity, or dust levels for a section—say, for sensitive electronics or pharmaceuticals. Partitions help you contain conditions rather than treating the entire facility as one giant room. - Modularity & Future Flexibility

Industrial partitioning systems often use panels that are demountable or reconfigurable. If your workflow changes, you can shift walls, enlarge or shrink areas, or remove partitions altogether. This ensures the layout can evolve with your business. - Cost Savings Over Permanent Construction

Building permanent walls is expensive and time-consuming. Partition systems are usually quicker to install, less expensive, and cause minimal disruption to ongoing operations.

What to Look for in a Good Partitioning System

- Material & Strength — steel panels, mesh, or composite materials that resist impact

- Height & Structure — full ceiling height or part-height, depending on need

- Acoustic & Fire Ratings — for zones that demand noise blocking or fire containment

- Doors, Windows & Visibility — glazed panels or windows let supervisors monitor without entering

- Ease of Reconfiguration — ability to dismantle and move segments

How OG Limited Approaches Partitioning

At OG Limited, partitioning isn’t an afterthought; it’s strategy. We start with a site survey, understand your workflow, then propose a layout that balances separation with access. Our systems use industrial-grade panels and frames with built-in flexibility. We integrate doors, glazed sections, and safety barriers in ways that look clean and function smooth. And when your operations change, we help you reconfigure, not rip out.

Partitioning is more than division—it’s control. It gives structure to your space, clarity to your workflow, and protection to your operations. Let OG Limited help you turn a broad warehouse hall into a precise, safe, efficient environment.